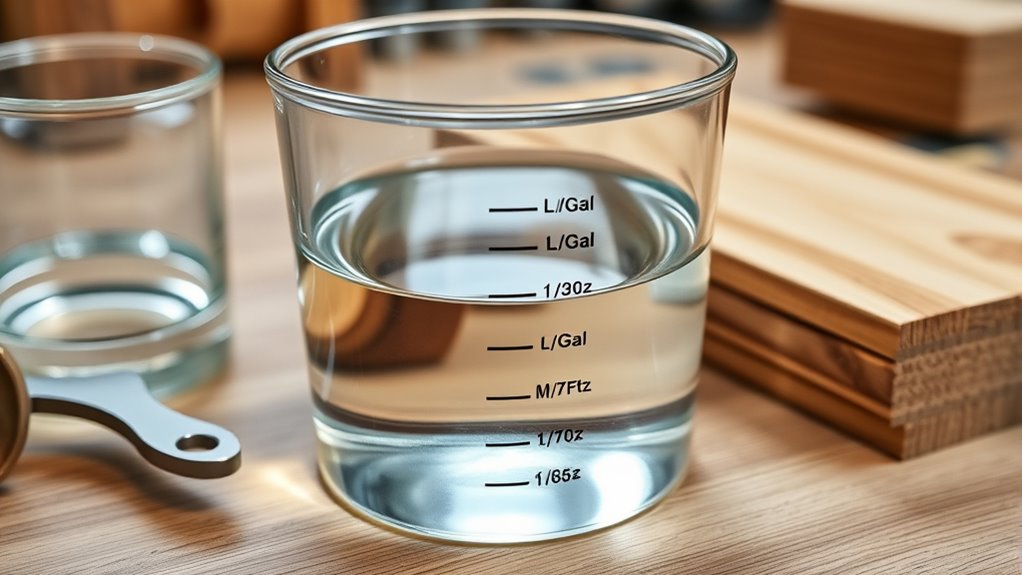

To clean sealed hardwood effectively, mix about 0.25 liters (one cup) of vinegar per 3.8 liters (one gallon) of water, which is roughly 0.065 L/m² or 1 oz per gallon. For larger areas, aim for about 1 liter per 4–8 square meters, or 0.25–0.5 liters per 10 square feet. Ensuring proper ratios protects the seal and keeps your floor looking great—continue exploring for more precise tips and techniques.

Key Takeaways

- Use a vinegar-water ratio of 1 oz vinegar per gallon (3.78 L) for gentle cleaning.

- For sealed hardwood, dilute commercial cleaners per manufacturer instructions, typically in ratios of 1:10 or as specified.

- Convert cleaning ratios to square meters or feet by adjusting the dilution volume to cover the desired area effectively.

- Measure solutions carefully to avoid over- or under-dilution, ensuring proper cleaning without damaging the sealant.

- Sealant reapplication generally requires about 1 gallon per 200-400 sq ft (18.6-37.2 m²), applied evenly with appropriate tools.

Sealed hardwood floors require a specific cleaning solution to maintain their shine and durability. Using the right mixture guarantees you don’t damage the surface or strip away the protective layer. When it comes to cleaning sealed hardwood, a common approach involves a mild solution blended with water, but understanding the proper ratios is vital for effective maintenance. You’ll want to pay attention to the application techniques, especially when using products like wood sealant, to keep your floors looking their best without causing harm.

For routine cleaning, a typical ratio is about 1 part white vinegar to 10 parts water, or roughly 1 ounce of vinegar per gallon of water. This gentle solution cleans without dulling the finish or breaking down the sealant. If you prefer commercial cleaners, look for products formulated specifically for sealed hardwood, and always follow the manufacturer’s recommended ratios. These are often available in concentrated forms, requiring dilution before application, and the instructions will specify whether to use a particular ratio per gallon or per square meter/foot.

When preparing your cleaning solution, precision matters. Using too strong a mixture can damage the wood’s protective layer, causing it to lose its luster or become vulnerable to scratches and stains. Conversely, an overly diluted solution might not clean effectively, leaving smudges or dirt behind. Always measure carefully and test your mixture on a small, inconspicuous area first to guarantee it doesn’t cause any adverse effects.

Applying the solution correctly involves more than just mixing it. Proper application techniques include using a soft microfiber mop or cloth that’s slightly damp—not soaked. Excess moisture can seep into seams or cracks, weakening the wood or damaging the sealant over time. When you mop, move with the grain of the wood, and avoid pressing down too hard. After cleaning, go over the floor with a dry microfiber cloth to remove any remaining moisture and prevent streaks. Additionally, regular maintenance using the correct cleaning ratios can extend the life of your hardwood floors significantly.

If you decide to reapply a wood sealant, understanding application techniques is just as vital. The process typically involves cleaning the surface thoroughly, allowing it to dry completely, and then applying the sealant evenly with a brush or roller. Follow the manufacturer’s instructions precisely, including recommended application ratios—often around 1 gallon of sealant per 200-400 square feet— and work in well-ventilated areas. Proper application techniques guarantee the sealant bonds well and creates a smooth, protective coating that enhances your floor’s durability and appearance.

Frequently Asked Questions

How Long Does the Sealing Solution Last Before Needing Replacement?

The sealing solution typically lasts about 1 to 2 years before needing replacement, depending on storage conditions. Its shelf life can be extended by keeping the container tightly sealed and storing it in a cool, dry place away from direct sunlight. Always check for signs of spoilage, like thickening or separation, before use. Proper storage tips ensure your solution remains effective and safe for sealing hardwood surfaces.

Can the Solution Mix Be Customized for Different Hardwood Types?

Yes, you can customize the solution mix for different hardwood variations by adjusting the mixing ratios. If you’re working with softer or more porous woods, you might need a stronger concentration for better sealing. Conversely, for harder or denser hardwoods, use lighter ratios to avoid over-sealing. Always test small batches first and tweak your custom mixing ratios accordingly, ensuring ideal adhesion and protection tailored to each hardwood type.

What Safety Precautions Are Necessary During Application?

You should always wear protective gear, like gloves, goggles, and a respirator, to prevent skin and eye contact and inhalation of fumes. Make certain proper ventilation procedures are in place by working in a well-ventilated area or using fans to disperse fumes. These safety precautions help protect you from potential hazards associated with the solution, making the application process safer and more effective.

How Does Humidity Affect the Solution’s Effectiveness?

Humidity impact can considerably reduce the solution’s effectiveness if moisture control isn’t maintained. High humidity levels introduce excess moisture, which can prevent proper curing and adhesion, leading to uneven sealing or longer drying times. To guarantee ideal results, you should monitor humidity and work in a controlled environment. Keeping humidity levels low helps the solution bond better, cures uniformly, and provides a durable, professional finish on your hardwood.

Is There a Recommended Storage Method for Leftover Solution?

Think of your leftover solution as a precious elixir that needs safeguarding. Store it in airtight containers to keep its magic intact, preventing evaporation and contamination. Maintain a cool, consistent temperature to slow chemical reactions and preserve its effectiveness. Avoid extreme heat or cold, which can cause separation or spoilage. Proper temperature control and sealed storage containers guarantee your solution stays potent, ready for the next application.

Conclusion

Now that you understand the precise ratios for sealing hardwood, remember that choosing the right mix isn’t just about numbers—it’s about protecting beauty and durability. Like a delicate balance between art and science, your solution mix combines careful measurements with a passion for craftsmanship. When you get these ratios right, you’re not just sealing a floor; you’re preserving its character for years to come. It’s the science of protection, and you hold the key.