To guarantee robot safety on wet floors, you need to calibrate sensors like accelerometers and proximity detectors regularly for accurate readings. Quick detection of slippery or unstable surfaces allows your robot to slow down or stop, preventing slips or collisions. Implementing clear emergency protocols enhances safety, especially when sensors detect sudden changes. Maintaining and testing these systems often makes a big difference. Keep exploring to learn more about creating a safer environment for your robot in wet conditions.

Key Takeaways

- Regularly calibrate sensors like accelerometers and proximity detectors to ensure accurate detection of slippery surfaces and obstacles.

- Implement emergency protocols such as automatic slowing or stopping when sensor data indicates wet, slippery conditions.

- Use sensor redundancy and layered safety systems to maintain reliable operation during wet-floor navigation.

- Conduct routine maintenance and scenario testing, including wet-floor simulations, to verify safety protocol effectiveness.

- Adapt safety measures dynamically based on sensor feedback to prevent slips, falls, and collisions in wet-floor environments.

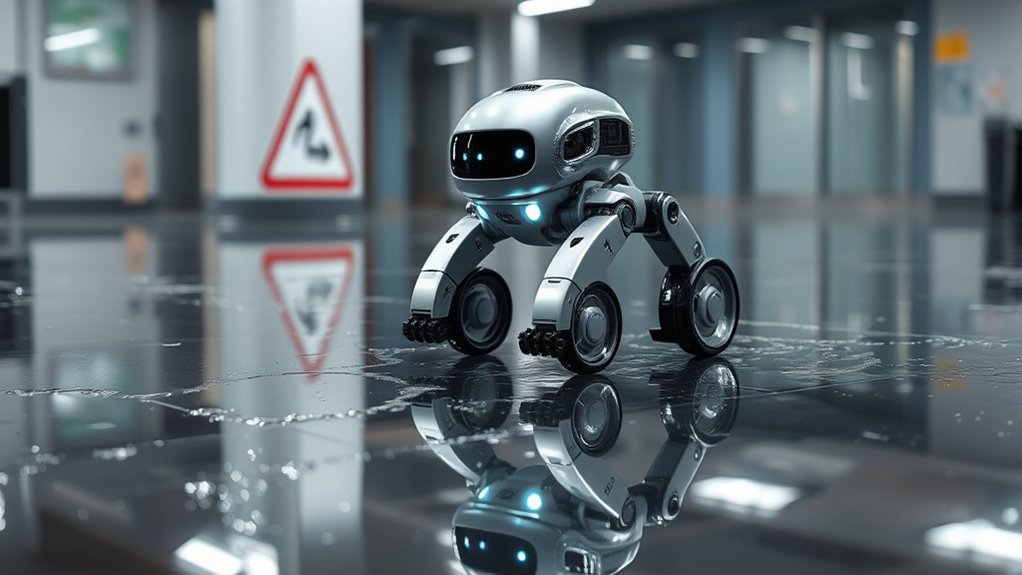

Wet-floor conditions pose important safety challenges for robots operating in various environments. When surfaces become slick and unpredictable, robots must adapt quickly to prevent accidents, damage, or injury. Proper sensor calibration becomes essential here. Sensors like accelerometers, gyroscopes, and proximity detectors need to be finely tuned to guarantee that the robot accurately perceives its surroundings, especially when surfaces are wet and surfaces’ friction changes. If these sensors aren’t calibrated correctly, the robot might misjudge its footing or proximity to obstacles, leading to slips, falls, or collisions. Regular sensor calibration helps maintain reliable readings, so your robot can respond appropriately to slipping hazards or unexpected obstacles caused by wet floors. Additionally, understanding the size limitations of tiny houses can inform the design of compact, efficient safety systems that fit within small spaces.

In addition to sensor calibration, having well-defined emergency protocols is critical. When a robot detects a slip, imbalance, or an imminent collision, it should immediately execute safety procedures to minimize risks. Emergency protocols might include stopping all movement, activating warning signals, or moving to a designated safe zone. These protocols are essential because they provide a structured response to unpredictable wet-floor conditions, reducing the chance of injury or equipment damage. You must guarantee that your robot’s emergency protocols are tested regularly and are capable of swift execution. Training your system to recognize the signs of potential failure, like abnormal sensor readings or sudden loss of stability, allows it to act proactively rather than reactively.

Moreover, integrating sensor calibration with emergency protocols enhances overall safety. For instance, if your robot detects a sudden change in sensor data indicating a slippery surface, it can automatically slow down or halt operations. This preemptive action can prevent accidents before they happen. You should also incorporate redundancy in sensors and protocols, so if one system fails or provides false data, others can compensate. This layered safety approach keeps the robot operating reliably even in tricky wet-floor conditions.

In practice, maintaining these safety measures involves regular maintenance routines, firmware updates, and scenario testing. Always verify that sensors are properly calibrated after any hardware adjustments or environmental changes. Simulate wet-floor scenarios to ensure emergency protocols activate correctly and swiftly. By focusing on precise sensor calibration and robust emergency protocols, you considerably improve your robot’s safety and operational effectiveness in slippery, wet environments. This dual approach ensures your robot can navigate wet floors confidently, reducing risks for personnel and equipment alike.

Frequently Asked Questions

How Do Robots Detect Wet Floors Automatically?

You can have robots detect wet floors automatically through sensors like moisture sensors or infrared cameras, which identify water presence. To guarantee accurate detection, you should regularly perform sensor calibration and stick to maintenance schedules. This keeps the sensors responsive and reliable, preventing slips or accidents. Proper calibration and maintenance help your robot adapt to changing conditions, ensuring safety on wet floors at all times.

What Are the Best Materials for Robot Waterproofing?

Think of your robot as a modern-day hero, needing armor against water. You should use waterproofing membranes like silicone or polyurethane coatings, which create a barrier against moisture. Corrosion-resistant materials such as stainless steel or certain plastics also guarantee durability. These choices protect internal electronics and mechanical parts, helping your robot operate safely and reliably on wet floors. Proper waterproofing is key to extending its lifespan and performance.

How Often Should Robot Sensors Be Inspected for Water Damage?

You should inspect your robot sensors regularly, ideally every one to two months, to prevent water ingress and guarantee proper sensor calibration. Frequent inspections help identify early signs of water damage, allowing you to take timely action. Focus on checking seals and waterproof coatings, especially after exposure to wet conditions. This proactive approach minimizes water ingress risks, maintains sensor accuracy, and extends your robot’s operational lifespan.

Are There Specific Certifications for Wet-Floor Robot Safety?

Yes, there are specific certifications for wet-floor robot safety. You should look for certifications based on industry standards like ISO or ANSI, which establish safety protocols for water resistance and electrical safety. These certification standards ensure your robots operate safely in wet environments. By choosing robots with these certifications, you reduce risks and ensure compliance, giving you confidence that safety protocols are thoroughly addressed for wet-floor conditions.

How Do Robots Handle Sudden Water Spills During Operation?

Imagine your robot as a cautious sailor, ready for sudden storms. When water spills occur, it relies on water sensor integration to detect the change instantly. This triggers emergency shutdown protocols, halting operations to prevent damage or accidents. You guarantee these safety features are active, so your robot responds swiftly to unexpected water, keeping everyone safe and the equipment protected, much like a vigilant sailor bracing for unpredictable waves.

Conclusion

Remember, even as robots become more advanced, safety remains your top priority—much like Icarus flying too close to the sun. When maneuvering wet floors, stay vigilant and follow proper protocols to prevent accidents. By doing so, you’ll guarantee your robotic helpers don’t become unintended fallers. Keep safety in mind, and you’ll avoid the pitfalls that can turn a smooth operation into a Greek tragedy. Stay alert, and let your robots work safely alongside you.