Balancing brush speed and torque is key to maximizing machinery performance, battery life, and durability. Running at high speeds with too much torque can cause overheating and wear, while too low speed limits power and efficiency. When you find the right mix, you guarantee smoother operation, longer component life, and better energy use. Understanding how these factors work together helps you maintain peak performance, so keep exploring to learn more about achieving that perfect balance.

Key Takeaways

- Balancing brush speed and torque ensures optimal machinery performance and prevents overheating or excessive wear.

- Higher brush speeds increase power output but drain battery faster and may cause component stress.

- Proper speed-torque tuning extends motor lifespan by reducing strain and maintenance needs.

- Optimizing these parameters improves energy efficiency and prolongs operational runtime.

- Maintaining the right balance enhances tool reliability, efficiency, and overall cost-effectiveness.

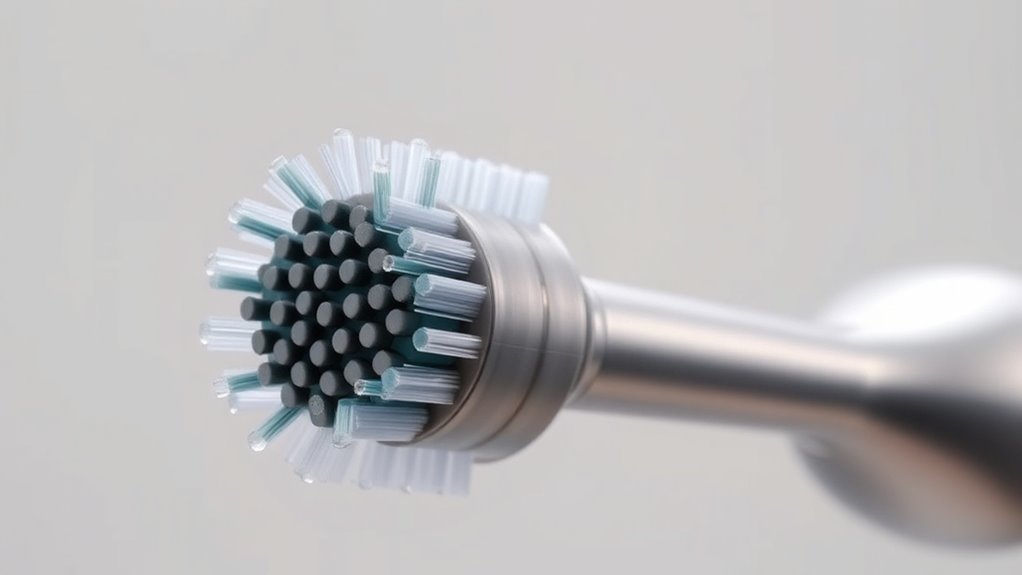

Understanding how brush speed and torque interact is essential for maximizing the performance of your machinery. When you’re operating equipment that relies on brushes, such as electric motors or power tools, the balance between speed and torque directly impacts efficiency and longevity. If you push the brush speed too high without considering torque, you risk overheating components, which can decrease battery efficiency and strain the motor. Conversely, running at too low a speed might save energy but reduce power output, making your machine less effective for demanding tasks. Finding the right mix is key to ensuring your equipment runs smoothly and reliably over time.

Balancing brush speed and torque ensures optimal efficiency and long-lasting machinery performance.

In terms of battery efficiency, higher brush speeds typically draw more current, which drains your power source faster. If your machine is designed to operate at an ideal speed, you’ll use less energy for the same workload, extending your battery life. On the other hand, if you frequently push for maximum speed without adjusting torque settings accordingly, you may find yourself recharging or replacing batteries more often. This is especially true in portable devices where battery life is critical. Managing brush speed in relation to torque allows you to operate at a level that maximizes runtime without sacrificing performance, ensuring you get the most out of each charge.

Motor durability is closely tied to how well you control these parameters. Running your motor at excessively high speeds under heavy torque loads can lead to faster wear and tear. The brushes, bearings, and windings endure more stress, increasing the risk of premature failure. Properly balancing brush speed and torque helps mitigate these issues by reducing unnecessary strain on the motor components. When you maintain a moderate, controlled speed aligned with the required torque, you prolong motor life, reducing maintenance costs and downtime. This careful management is particularly important in industrial or long-term applications, where consistent operation over years matters most.

Additionally, understanding the performance tuning options available for specific Kia models can help maximize vehicle efficiency and longevity, similar to how balancing brush speed and torque optimizes machinery. Ultimately, understanding the interaction between brush speed and torque empowers you to tune your machinery for peak performance. By paying attention to how these factors influence battery efficiency and motor durability, you can make smarter adjustments that save energy, extend equipment lifespan, and improve overall productivity. Whether you’re working with handheld tools, industrial motors, or robotics, this knowledge helps you operate more effectively, ensuring your equipment remains reliable and efficient under various conditions. Balancing speed and torque isn’t just about power—it’s about optimizing how your machine uses energy and withstands ongoing use, making your work smoother and more cost-effective in the long run.

Frequently Asked Questions

How Does Brush Speed Affect Overall Tool Lifespan?

You might notice that higher brush speeds can increase wear rate, which can shorten your tool’s lifespan. When you run the brush too fast, it strains the motor and drains battery life faster, leading to quicker component degradation. To maximize your tool’s durability, keep the speed moderate, allowing the brush to operate efficiently without accelerating wear. This balance helps extend overall battery life and maintains peak performance longer.

Can Adjusting Torque Improve Precision in Delicate Tasks?

You can definitely improve precision in delicate tasks by adjusting torque. When you fine-tune torque adjustment, you control the force applied, reducing the risk of over-penetration or damage. This coincidence of careful control and accuracy enhancement ensures your work stays accurate and clean. By customizing torque settings, you gain better command over your tool, making intricate tasks smoother and more reliable, especially when precision is vital.

What Are the Safety Considerations Related to High Brush Speeds?

You should always wear personal protective equipment, like safety goggles and gloves, when working with high brush speeds to prevent injuries from debris or accidental contact. Keep an emergency shutdown accessible to quickly stop the equipment if needed. Be aware of your surroundings, avoid loose clothing, and make certain of proper training before operating at high speeds. These precautions help minimize risks and keep you safe during intensive brushing tasks.

How Do Different Materials Influence Optimal Brush Speed?

Think of abrasive materials as rugged terrain and soft surfaces as delicate petals. You should adjust your brush speed accordingly: higher speeds work well on tough, abrasive materials to guarantee efficient cleaning, while slower speeds prevent damage on soft surfaces. By matching your brush speed to the material’s toughness, you achieve thorough results without risking harm, making your work both effective and safe.

Is There a Trade-Off Between Speed and Torque for Efficiency?

Yes, there’s a trade-off between speed and torque for efficiency. When you aim for speed optimization, you often sacrifice torque, which can reduce power and performance. Conversely, balancing torque ensures you maintain sufficient force for tough tasks without sacrificing too much speed. By carefully managing this torque balancing, you can enhance overall efficiency, guaranteeing your brush operates smoothly and effectively across different materials and tasks.

Conclusion

So, when choosing your tools, do you prioritize speed or torque? Remember, both play vital roles in your project’s success. A higher brush speed can make quick work of light tasks, while greater torque handles tougher jobs with ease. Ultimately, understanding how these factors work together helps you select the right tool for the job. Isn’t it worth investing a little time to master what truly matters in your work?