If you want to clean more effectively in your restaurant, cylindrical equipment usually performs better because its smooth surfaces are easier to scrub, and fewer crevices mean less grime hiding. Cylinders also use space more efficiently, making them great for tight kitchens. Flat discs, however, are quick to wipe down and work well in open layouts. To discover which suits your needs best and optimize your cleaning, keep exploring your options.

Key Takeaways

- Cylindrical equipment offers smooth surfaces that are easier to scrub and less prone to grime buildup.

- Flat discs allow for quick cleaning of broad surfaces, making surface wiping more efficient.

- Cylinders typically have fewer seams and crevices, reducing areas where dirt can hide.

- Discs may require more space around them but enable rapid surface cleaning in open layouts.

- Both shapes benefit from advanced cleaning tools, but cylindrical designs generally enhance hygiene and space efficiency.

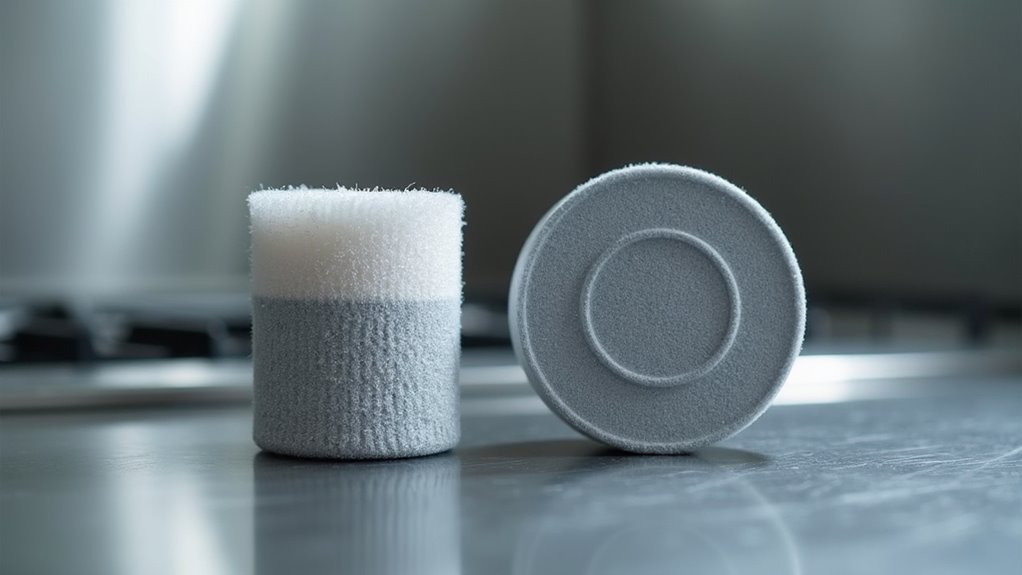

When choosing between cylindrical and disc-shaped equipment for your restaurant kitchen, understanding their differences can considerably impact your workflow and efficiency. These shapes influence how effectively you clean and how well you utilize your space. If cleaning efficiency is a priority, you’ll want to consider how each design interacts with cleaning tools and processes. Cylindrical equipment often features smooth, continuous surfaces that are easier to scrub without corners or crevices where grime can hide. Their rounded shape allows cleaning tools to glide effortlessly around the entire surface, reducing the time and effort needed for thorough sanitation. This can lead to better hygiene standards and quicker turnaround times between cleaning cycles.

On the other hand, disc-shaped equipment offers a different set of advantages. Because of their flat, broad surfaces, discs are typically easier to wipe down quickly, especially when used for equipment like prep stations or flat-top grills. Their shape enables you to cover large areas with minimal effort, making them highly effective for rapid cleaning tasks. However, if your equipment has protrusions or edges, cleaning can become more complicated, potentially trapping debris in corners or seams. That’s why choosing a disc with minimal joints or seams can enhance cleaning efficiency, saving you time and reducing the risk of contamination.

Disc-shaped equipment simplifies quick cleaning with broad surfaces, but watch for edges and seams that trap debris.

Space optimization is another essential factor when selecting between these shapes. Cylindrical units tend to be more space-efficient in tight quarters because they can be stacked or integrated into modular setups. Their rounded form allows for seamless placement alongside other equipment, often occupying less horizontal space. Conversely, discs may require more room around their perimeter, especially if they are part of larger machinery or need clearance for maintenance and cleaning. If your kitchen layout is compact, cylindrical equipment might help you maximize available space without sacrificing functionality.

Additionally, consider how each shape influences workflow. Cylindrical designs often facilitate easier movement around the equipment, as they typically have fewer sharp edges or protrusions. This can improve overall efficiency, especially in busy kitchens where quick access and movement are essential. Discs, while straightforward to clean and sometimes more accessible for surface wiping, might require more careful planning to avoid clutter or congestion, especially if multiple units are used side by side.

Furthermore, advancements in cleaning technology like specialized brushes and automated systems can enhance the maintenance of both shapes, making the decision even more tailored to your operational needs. Ultimately, your choice depends on the specific tasks and layout of your kitchen. Cylindrical equipment might excel in environments where thorough cleaning and space-saving are critical, while disc-shaped units can be advantageous for quick surface cleaning and open layouts. By weighing these factors, you can select the shape that best enhances your cleaning efficiency and optimizes your kitchen space.

Frequently Asked Questions

Which Material Is More Resistant to Corrosion in Kitchen Environments?

You’ll find that stainless steel offers superior corrosion resistance and material longevity in kitchen environments. Its durable surface withstands moisture and harsh cleaning agents, making it less prone to rust. Compared to other materials, stainless steel maintains its integrity longer, ensuring your equipment stays in top shape. For a reliable, long-lasting option that resists corrosion, stainless steel is the best choice for kitchen applications, keeping your workspace safe and hygienic.

How Do Cylindrical and Disc Mop Heads Compare in Durability?

You’ll find that cylindrical mop heads generally have a longer lifespan due to their superior material durability, making them more resistant to wear and tear. Disc mop heads, while easier to maneuver, tend to wear out faster, especially with frequent use. When choosing between the two, consider how often you need durability for heavy-duty cleaning tasks, as cylindrical types typically withstand tougher conditions longer, ensuring better overall mop head lifespan.

Are There Specific Cleaning Solutions Better Suited for One Type?

Yes, certain cleaning solutions work better with specific mop head materials. For cylindrical mop heads, you should use solutions that won’t degrade the fibers, like neutral pH cleaners. Disc mop heads, often made of microfiber, are compatible with a wider range of cleaning solutions, including disinfectants and degreasers. Always check cleaning solution compatibility to prevent damage and guarantee effective cleaning, regardless of whether you’re using a cylindrical or disc mop head.

How Does Mop Head Design Impact Ease of Storage and Replacement?

Imagine you’re managing a busy restaurant, and your mop head design affects your workflow. Cylindrical mop heads often offer better storage convenience because they fit neatly into compact holders, while disc heads are easier to replace due to their simple attachment mechanisms. The design directly impacts ease of storage and replacement, making cylindrical heads ideal for space-saving needs, and disc heads perfect when quick swaps are a priority.

Which Type Is More Cost-Effective Over the Long Term?

You’ll find that cylindrical mops are more cost-effective over the long term because they typically have lower initial purchase prices and easier maintenance. Their design reduces maintenance costs since they’re simpler to clean and replace. Disc mops, while more durable, can incur higher replacement and upkeep expenses. Overall, choosing a cylindrical mop saves you money through better cost efficiency and lower ongoing maintenance costs, making it a smarter investment for your kitchen.

Conclusion

When it comes to choosing between cylindrical and disc scrubbers, you’ve got to pick what works best for your kitchen’s needs. Both clean effectively, but understanding their strengths helps you make a smart decision. Remember, sometimes it’s the little things that make a big difference. Don’t put all your eggs in one basket—try both and see which one truly gets the job done. After all, a clean kitchen runs like a well-oiled machine.