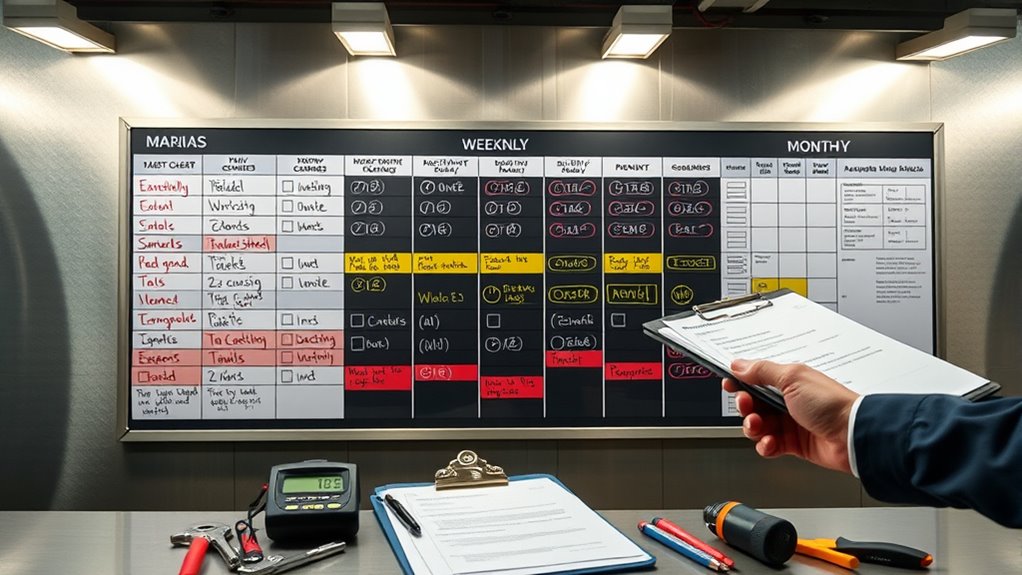

Implementing a proper maintenance schedule involves routine tasks performed daily, weekly, and monthly to keep your equipment running smoothly. Daily checks include quick inspections and cleaning, while weekly tasks involve deeper inspections, calibration, and adjustments. Monthly routines focus on detailed reviews, data analysis, and component replacements. Following this structured plan helps prevent breakdowns, extend equipment life, and save costs. Keep exploring to discover how to customize these tasks for your specific needs and maximize efficiency.

Key Takeaways

- Daily maintenance includes quick checks, cleaning, and immediate repairs to ensure equipment runs smoothly.

- Weekly tasks involve thorough inspections, calibration, tightening connections, and replacing worn parts.

- Monthly procedures consist of detailed performance reviews, data analysis, firmware updates, and component replacements.

- Structured schedules prevent breakdowns, extend equipment lifespan, and improve operational efficiency.

- Using scheduling software helps automate reminders and track completion of daily, weekly, and monthly maintenance tasks.

Regular maintenance schedules are essential to keep your equipment running smoothly and prevent costly breakdowns. When you implement a well-structured plan, you take proactive steps to address potential issues before they escalate. Preventive measures, such as routine inspections and timely repairs, form the backbone of effective maintenance. Using scheduling software can streamline this process, helping you set reminders and track tasks seamlessly. This technology ensures nothing slips through the cracks, so your equipment receives attention exactly when needed, avoiding unexpected downtimes.

Daily maintenance is all about quick checks and immediate actions that keep your systems operational. Each day, you should inspect critical components, clean surfaces, and verify that machines are functioning within normal parameters. Simple tasks like clearing debris, lubricating moving parts, and checking for leaks can considerably extend equipment lifespan. This routine allows you to catch minor issues early, preventing them from becoming larger problems. With scheduling software, you can automate reminders for these daily tasks, ensuring they’re never overlooked, especially during busy periods. This approach keeps your team accountable and maintains consistency across shifts.

Weekly maintenance dives a bit deeper, requiring you to dedicate more time to thorough inspections and minor adjustments. During this period, you should review operational metrics, test safety features, and perform calibration checks. It’s also wise to clean filters, tighten loose connections, and replace worn-out parts before they cause failures. Incorporating weekly preventive measures into your schedule helps you identify patterns or recurring issues, enabling you to address root causes. Scheduling software can generate weekly checklists, assign tasks to team members, and track completion rates, making sure your maintenance remains organized and efficient. This proactive stance minimizes the risk of disruptions and prolongs equipment life.

Monthly maintenance involves detailed reviews, including thorough inspections, performance audits, and system overhauls if necessary. At this stage, you should analyze data logs, update firmware or software, and replace components approaching end-of-life. It’s also an ideal time to review your maintenance records, identify trends, and adjust your strategies accordingly. Regularly scheduled monthly tasks guarantee your equipment stays in peak condition and helps you plan for future upgrades or replacements. Using scheduling software to set recurring monthly tasks ensures consistent execution and provides historical data to inform your decisions. This organized approach reduces emergency repairs and enhances overall operational reliability.

Incorporating daily, weekly, and monthly maintenance routines, supported by scheduling software, creates a thorough preventative approach. Staying disciplined with these intervals guarantees your equipment remains reliable, efficient, and safe, ultimately saving you time and money in the long run.

Frequently Asked Questions

How Do I Prioritize Maintenance Tasks Across Different Schedules?

You should prioritize maintenance tasks by focusing on preventive planning, identifying critical equipment, and evaluating potential risks. Allocate resources efficiently by scheduling urgent issues first, then addressing less critical tasks. Use a risk-based approach to balance daily, weekly, and monthly tasks, ensuring essential preventive measures are completed on time. Regularly review and adjust your schedule to stay ahead of equipment failures, maximizing uptime and safety.

What Are Common Signs Indicating the Need for Urgent Maintenance?

You should act quickly if you notice unusual noises, leaks, or overheating—these often signal urgent maintenance needs. Statistically, 60% of equipment failures are due to overlooked signs. By implementing preventive measures and following safety protocols, you can catch issues early and avoid costly breakdowns. Stay vigilant and respond promptly to these signs to guarantee safety and keep your equipment running smoothly.

How Can I Track Maintenance History Effectively?

To track maintenance history effectively, you should use digital logs and maintenance software. These tools help you record every service, repairs, and inspections systematically, making it easy to access past data quickly. Regularly update the logs after each maintenance task, and utilize software features like reminders and reports to stay organized. This approach guarantees you have a clear history, reducing downtime and helping plan future maintenance efficiently.

What Tools Are Essential for Routine Maintenance?

You need essential tools like maintenance checklists and a tool inventory to streamline routine maintenance. Checklists help you stay organized and guarantee no step is missed, while a tool inventory keeps track of all your equipment and supplies. Use digital apps or spreadsheets to manage these tools efficiently. Regularly update your checklists and inventory to prevent delays and maintain smooth operations, making your routine maintenance more effective and less stressful.

How Do Maintenance Schedules Vary for Different Industries?

Maintenance schedules vary like a tailored suit across industries. You adapt your routine to meet industry compliance and safety standards, ensuring equipment stays in top shape. For example, manufacturing might require daily inspections, while healthcare might prioritize weekly sterilization checks. You need to stay flexible, adjusting frequency based on operational demands and regulatory requirements, so your maintenance plan fits perfectly, keeping safety standards high and downtime low.

Conclusion

Keeping up with daily, weekly, and monthly maintenance tasks ensures your equipment runs smoothly—think of it as your personal DeLorean, always ready for the next adventure. Don’t let neglect turn your high-tech spaceship into a rusted relic. Staying consistent with these schedules helps you avoid costly repairs and keeps everything in tip-top shape. Remember, even Doc Brown would agree that a little regular upkeep today keeps the future running like clockwork.