To keep your sweeper running smoothly, routinely inspect and replace filters to maintain airflow and dust control. Check belts regularly for signs of wear, cracking, or stretching, and verify they’re properly tensioned to prevent slipping or damage. Don’t forget to empty the hopper often and inspect for blockages or leaks, while keeping tires properly inflated for better traction. Continuing with proper maintenance ensures your sweeper stays efficient and reliable — learn more about optimizing your upkeep now.

Key Takeaways

- Regularly inspect and replace filters to maintain airflow, dust suppression, and operator health.

- Check belts for wear, cracking, or stretching, and replace or tension them properly for reliable operation.

- Clean and empty the hopper frequently to prevent blockages and ensure effective debris collection.

- Maintain proper tire inflation and alignment to optimize traction and reduce component wear.

- Conduct routine inspections of filters, belts, and hopper seals to prevent damage and extend sweeper lifespan.

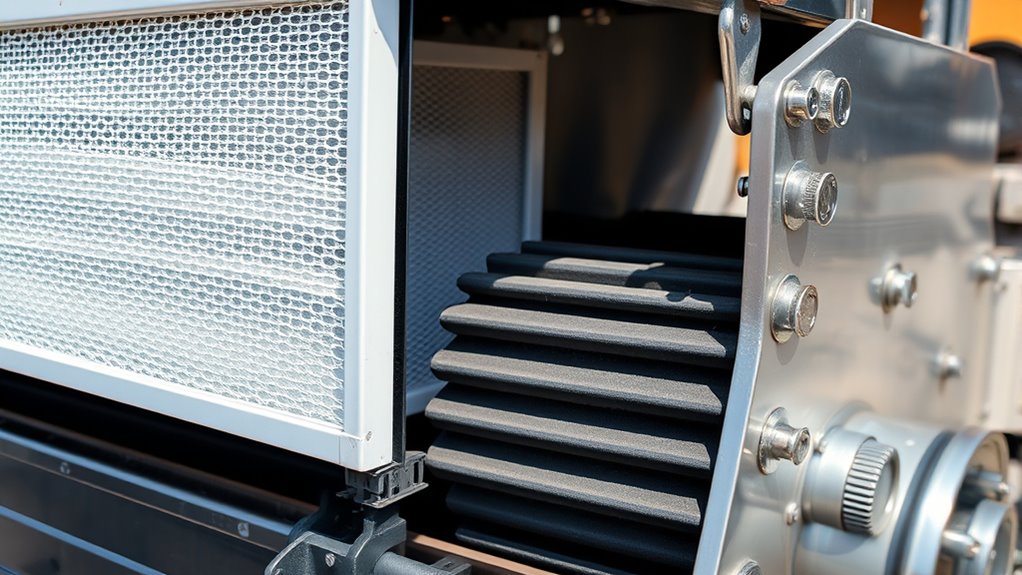

Keeping your sweeper in top condition is essential for effective cleaning and long-lasting performance. Proper maintenance ensures it operates efficiently, saving you time and money in the long run. One critical aspect of maintenance involves inspecting and replacing filters regularly. Clean filters are vital for dust suppression; when filters are clogged or dirty, dust particles can escape back into the environment, reducing air quality and cleaning effectiveness. By keeping filters clean and replacing them as needed, you prevent dust buildup, improve airflow, and maintain the sweeper’s suction power. This not only enhances cleaning performance but also helps protect the health of operators and nearby workers. Additionally, maintaining clean filters reduces the strain on the sweeper’s motor, which can prolong its lifespan. Regularly checking the filter condition ensures optimal dust control and airflow efficiency.

Another crucial component to monitor is the belts. Belts transfer power from the engine to various moving parts, so their condition directly impacts the sweeper’s functionality. Regularly inspecting belts for signs of wear, cracking, or stretching is essential. Worn or damaged belts can slip or break, causing operational interruptions. Replacing them promptly keeps the sweeper running smoothly and prevents costly repairs. Proper tensioning of belts also plays a role here; overly tight belts can cause excessive wear on both the belts and the pulleys, while loose belts may slip, reducing efficiency. Proper tensioning extends belt life and ensures consistent power transfer. When belts are in good condition, they contribute to the overall reliability of your sweeper.

The hopper, where debris and waste are collected, also requires regular attention. An overfilled hopper can hinder the sweeper’s ability to pick up debris efficiently, leading to incomplete cleaning. Make it a habit to empty the hopper frequently and check for any blockages or damage that could impede its function. Regularly inspecting the hopper’s seals and hinges helps prevent leaks and ensures easy access for cleaning. When it comes to tire wear, keeping tires properly inflated and aligned is crucial. Excessive tire wear can reduce traction and maneuverability, making the sweeper harder to control and increasing the risk of damage to the tires and other components. Proper tire maintenance not only improves handling but also minimizes vibration and wear on other parts, contributing to a smoother operation overall.

Frequently Asked Questions

How Often Should Sweeper Filters Be Replaced?

You should replace sweeper filters every 1 to 3 months, depending on usage and filter condition. Regular filter cleaning helps maintain peak performance, but if you notice reduced suction or excessive dust, it’s time for a replacement. Follow the belt replacement schedule advised by your sweeper’s manufacturer, usually every 6 to 12 months, to prevent strain on the motor and guarantee efficient operation.

What Are Signs of Worn-Out Belts?

Worn-out belts are like a slipping gear, and you’ll notice fraying edges or cracks during belt inspection. You might also hear squealing sounds or see the belt slipping when in use. Regular tension adjustment helps prevent wear, but if the belt feels loose or shows signs of excessive wear, it’s time to replace it. Stay vigilant and check your belts often to keep your sweeper running smoothly.

How to Prevent Hopper Blockages?

To prevent hopper blockages, you should guarantee proper hopper design that promotes smooth debris flow. Regularly inspect for debris accumulation and remove it before it builds up. Avoid overloading the hopper and keep screens or grates clear. Implement routine maintenance and train operators to recognize early signs of clogs. By doing so, you’ll minimize blockages, maintain efficiency, and extend the lifespan of your sweeper.

What Type of Filters Are Most Effective?

Imagine you’re using a HEPA filter on your sweeper, and it considerably boosts dust collection. HEPA filters are among the most effective because of their high filter efficiency, capturing tiny particles and improving air quality. They prevent dust from escaping back into the environment, making your cleaning more thorough. For peak performance, make certain regular maintenance and replacement, so your sweeper keeps dust collection efficient and consistent.

Can Maintenance Be Done During Operation?

Yes, maintenance can often be done during operation, but you need to be cautious. To prevent dust accumulation and guarantee operator safety, perform inspections quickly and use proper protective gear. Focus on checking filters, belts, and hoppers without disrupting the sweeper’s workflow. Regular, mindful maintenance helps keep the equipment running smoothly, minimizes dust risks, and safeguards everyone involved. Always follow the manufacturer’s safety guidelines during these tasks.

Conclusion

Just like a well-tuned engine keeps a car running smoothly, regular maintenance of filters, belts, and hoppers guarantees your sweeper stays at peak performance. Think of it as tending a garden—care today yields a lush, productive tomorrow. Neglecting these parts is like ignoring the steady heartbeat of your equipment, risking breakdowns and delays. Stay proactive, keep everything clean and aligned, and your sweeper will serve you faithfully, moving forward with the quiet assurance of a well-oiled machine.