If you’re looking for the top forklift-towed industrial scrubbers in 2025, I recommend considering models that combine durability, efficiency, and ease of use. These include compact options with foldable handles, large-capacity tanks, and heavy-duty construction built for tough environments. For large spaces, equipment with extended cleaning paths and power options like electric or gas make a big difference. Keep in mind maneuverability and maintenance features to guarantee long-term performance. If you want to know more, you’ll find useful details below.

Key Takeaways

- Top forklift-towed scrubbers feature compact designs with user-friendly controls and quick-maintenance systems for efficient operation.

- Heavy-duty models with large tanks and rugged construction excel in large-scale industrial and outdoor cleaning tasks.

- Selection depends on area size, with larger tanks and higher coverage rates suited for extensive spaces over 5,000 sq ft.

- Maneuverability features like adjustable handles and swivel wheels enable effective cleaning in tight or obstacle-rich environments.

- Durable materials and easy maintenance ensure long-lasting performance in demanding industrial settings.

Global Industrial Electric Floor Scrubber

Looking for an efficient, easy-to-maneuver scrubber that can handle large commercial spaces? The Global Industrial Electric Floor Scrubber might be just what you need. It features a 13-inch cleaning path and a foldable handle, making storage and transport simple. With a 75-foot power cord, you can cover up to 5,240 square feet per hour, boosting productivity. Despite its compact size, it includes a 4-gallon recovery tank, perfect for continuous cleaning. Weighing 121 pounds, it’s sturdy yet manageable. Designed for industrial use, it requires no batteries and comes with an easy-to-follow assembly guide. It’s a solid option for demanding environments.

Best For: Commercial cleaning crews and industrial facilities seeking an efficient, maneuverable electric floor scrubber for large areas.

Pros:

- Compact design with a 13-inch cleaning path for easy maneuverability

- No batteries required, reducing maintenance and operational costs

- Long 75-foot power cord for extensive coverage and productivity

Cons:

- Weighs 121 pounds, which may be challenging for some users to lift or transport

- Mixed customer reviews with an average rating of 3.0 stars, indicating varied user satisfaction

- Limited to a 4-gallon recovery tank, which may require frequent emptying during large cleaning jobs

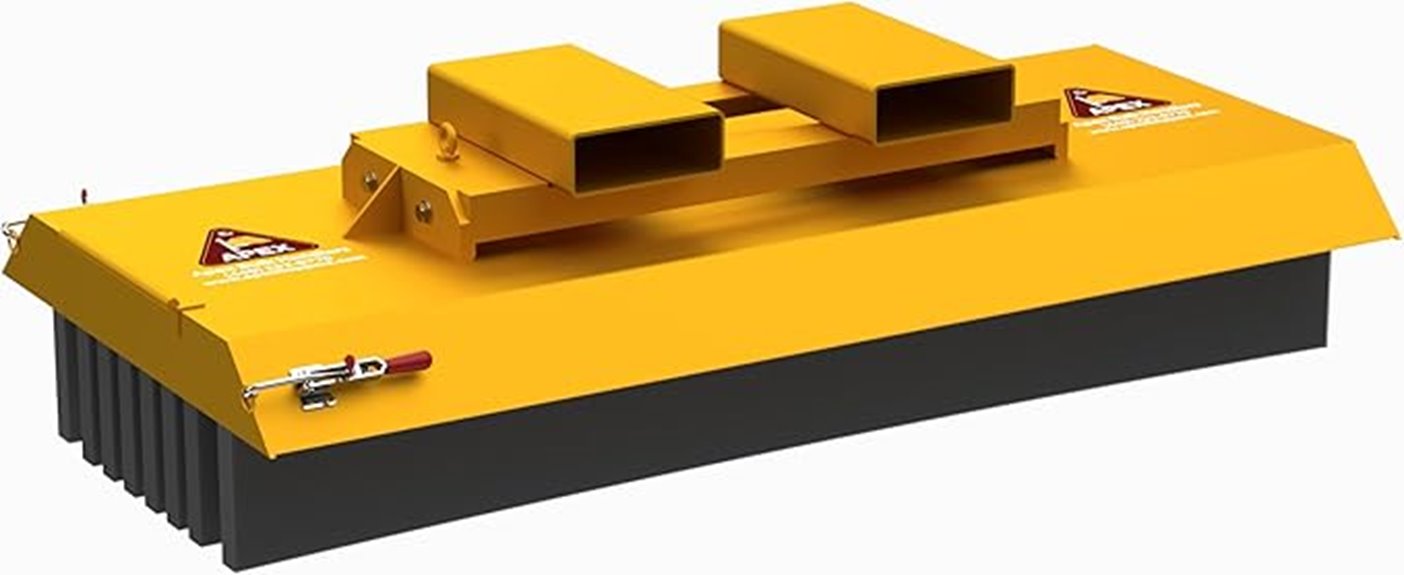

Apex 60” 6-Row Forklift Broom

If you’re searching for a heavy-duty broom that can handle large-scale cleaning tasks with ease, the Apex 60” 6-Row Forklift Broom is an excellent choice. Weighing 285 lbs, it’s built for both indoor and outdoor use, perfect for construction sites, warehouses, and landscaping. Its rugged ¼” solid steel body, alloy steel handle, and polypropylene bristles guarantee durability and reliable performance in demanding environments. The quick-change bristle system makes maintenance fast and simple, minimizing downtime. With a versatile design that sweeps dust, gravel, snow, and debris efficiently, this broom guarantees clean, safe, and productive workspaces across various industries.

Best For: heavy-duty construction, manufacturing, landscaping, and industrial environments requiring efficient large-area cleaning.

Pros:

- Durable construction with a ¼” solid steel body and alloy steel handle for long-lasting use

- Quick-change bristle system for fast, hassle-free maintenance and minimal downtime

- Versatile design effectively sweeps dust, gravel, snow, and debris on various surfaces

Cons:

- Heavy weight of 285 lbs may require assistance for handling and storage

- Large size (60”) may be cumbersome in tight or confined spaces

- Made in the USA, which could lead to higher cost compared to imported alternatives

FPE – Forklift Brush Set Clark 1813049 Hacus Aftermarket – New

The FPE Forklift Brush Set Clark 1813049 Hacus Aftermarket stands out as an ideal replacement part for Clark forklift operators seeking reliable maintenance solutions. This new, high-quality aftermarket set is designed specifically for Clark forklifts, ensuring a perfect fit and peak performance. Manufactured in China, it offers a cost-effective alternative without sacrificing durability. Whether for routine maintenance or replacing worn-out brushes, this set provides the reliability needed for efficient cleaning operations. I recommend it for anyone looking to keep their forklift in top condition, especially when upgrading or maintaining industrial scrubbers in demanding environments.

Best For: forklift operators and maintenance teams seeking reliable, cost-effective replacement brushes for Clark forklifts to ensure optimal cleaning performance.

Pros:

- High-quality aftermarket part that offers durability comparable to OEM components

- Designed specifically for Clark forklifts, ensuring a perfect fit and easy installation

- Cost-effective alternative manufactured in China without compromising performance

Cons:

- Being an aftermarket product, it may lack some of the original manufacturer’s branding or packaging

- Made in China, which might concern some users regarding supply chain or quality perceptions

- Does not include all possible accessories or components that might be included with OEM sets

Global Industrial Electric Walk-Behind Floor Scrubber

The Global Industrial Electric Walk-Behind Floor Scrubber stands out for its efficient coverage, making it ideal for large-scale cleaning tasks. With a 17-inch cleaning path, it quickly covers extensive areas, saving time. Its 9.2-gallon solution tank and 10.5-gallon recovery tank ensure continuous operation without frequent refills. The corded design includes an 82-foot power cord for added flexibility. Built with durable materials like aluminum and polypropylene, it’s sturdy yet lightweight at 189.6 pounds. Customers praise its performance, giving it a perfect 5-star rating. Overall, it’s a reliable, efficient choice for demanding industrial cleaning needs.

Best For: large-scale industrial facilities and commercial spaces requiring efficient, continuous cleaning with minimal downtime.

Pros:

- High-capacity tanks (9.2-gallon solution and 10.5-gallon recovery) enable longer cleaning sessions without frequent refills.

- 17-inch cleaning path allows for quick coverage of extensive areas, increasing productivity.

- Durable construction with aluminum and polypropylene ensures long-lasting performance in demanding environments.

Cons:

- Heavy weight of 189.6 pounds may require additional effort to maneuver or transport.

- Corded design limits mobility compared to battery-powered alternatives.

- Only available in one size (17-inch cleaning path), which may not suit smaller or more precise cleaning needs.

Global Industrial 2 Cu Yd Gray Medium Duty Self Dumping Forklift Hopper

For demanding material handling tasks, the Global Industrial 2 Cu Yd Gray Medium Duty Self Dumping Forklift Hopper stands out due to its robust 4,000-pound capacity and durable 11-gauge steel construction. Measuring 57W x 64L x 46H inches, it features three 28.5-inch fork pockets for secure attachment. Its design allows automatic dumping by balancing to roll forward when loaded, then returning upright for reloading. Continuous welding prevents leaks, while smooth edges and extended sides improve safety and minimize spillage. Customers praise its quick delivery, high craftsmanship, and reliable performance across different settings, making it a valuable addition for efficient, safe material handling.

Best For: industrial facilities, construction sites, and warehouse operations requiring durable, efficient, and safe material handling solutions.

Pros:

- Robust 4,000-pound capacity with durable 11-gauge steel construction for long-lasting use

- Automatic dumping feature that balances to roll forward when loaded, ensuring easy and safe unloading

- Extended sides and smooth edges enhance safety, minimize spillage, and improve structural integrity

Cons:

- Size may be too large for smaller or confined workspaces

- Heavier weight could require additional effort or equipment for movement when empty

- Limited color options, primarily available in gray, which may not suit all aesthetic or branding needs

Global Industrial Low-Profile Self-Dumping Forklift Hopper

A compact, low-profile design makes the Global Industrial Self-Dumping Forklift Hopper ideal for tight spaces where maneuverability is essential. Its 1/4 cubic yard capacity supports up to 6,000 pounds, making it perfect for handling overflow from dust collectors or waste in confined areas. The hopper includes a 4L pull chain for manual self-dumping, simplifying operation. With overall dimensions of roughly 46 inches wide and just over 21 inches high, it easily fits under dust ports and in narrow passages. This small, efficient hopper is a great choice for targeted waste collection, especially when space is limited and precise maneuvering is critical.

Best For: industrial facilities and maintenance teams needing a compact, easy-to-maneuver hopper for waste collection in tight spaces.

Pros:

- Compact low-profile design fits in narrow or confined areas

- Supports up to 6,000 lbs, suitable for heavy-duty waste collection

- Manual self-dumping with a simple pull chain for ease of use

Cons:

- Small capacity (1/4 cubic yard) may require multiple loads for larger waste volumes

- Product images do not reflect actual size, which could lead to underestimating dimensions

- Limited to manual operation; not motorized or automated

Factors to Consider When Choosing a Forklift‑Towed Industrial Scrubber

When selecting a forklift-towed industrial scrubber, I focus on the size of the area I need to clean, ensuring the machine’s capacity matches my workload. I also consider the power source compatibility and tank capacity to keep operations smooth and efficient. Finally, I look at maneuverability, durability, and build quality to find a scrubber that’s reliable and easy to handle over time.

Cleaning Area Size

Choosing the right forklift-towed industrial scrubber depends heavily on the size of the area you need to clean. For large spaces over 5,000 sq. ft., I recommend models with high coverage rates, capable of cleaning quickly and efficiently. The width of the cleaning path, usually between 13 and 17 inches, also impacts how fast you can cover an area—larger paths mean less time overall. If your facility is extensive, select a machine with large solution and recovery tanks, over 9 gallons, to reduce downtime. Maneuverability matters too; small machines excel in tight spots, while larger units are better suited for open spaces. Carefully evaluating your total cleaning area ensures your scrubber can operate continuously without frequent stops, maximizing productivity.

Power Source Compatibility

Matching the power source of your forklift-towed industrial scrubber to your facility’s utilities and operational needs is vital for smooth and efficient cleaning. Electric models need access to outlets or extension cords and may require grounding considerations to guarantee safety. Gas-powered scrubbers demand a reliable fuel supply and proper ventilation to handle exhaust emissions. Battery-powered scrubbers offer cordless operation and quick recharge times but need compatible charging stations and plans for battery replacement. It’s also essential to verify if the power cord length and plug type fit your workspace layout and safety standards. Additionally, consider how the power source impacts maintenance, operational costs, and compliance with environmental regulations. Choosing the right power source guarantees high performance and aligns with your facility’s infrastructure and safety protocols.

Tank Capacity Needs

Selecting the appropriate tank capacity for your forklift-towed industrial scrubber depends on the size of your cleaning area and the type of debris you encounter. Larger tanks, like 9.2 gallons for solution and 10.5 gallons for recovery, allow for longer cleaning sessions without frequent refills, ideal for extensive or heavy-duty tasks. Smaller tanks, around 4 gallons, are better suited for quick or light-duty cleaning but require more frequent emptying. If your area is large or involves stubborn debris, I recommend a scrubber with at least 5 gallons of solution and recovery capacity. For continuous, large-scale cleaning operations, heavy-duty models with over 17 gallons can considerably boost efficiency, reducing downtime and increasing productivity. Matching tank size to your needs helps optimize overall cleaning performance.

Maneuverability Features

When evaluating maneuverability features, I focus on how easily the scrubber can navigate tight spaces and obstacles. I look for models with compact dimensions and a low turning radius, which make maneuvering in confined areas smoother. Adjustable or steerable handles and wheel configurations are vital for precise control around obstacles, reducing operator effort. Ergonomic control panels also help facilitate accurate steering and directional changes, especially during complex maneuvers. Swiveling or caster wheels enhance agility, allowing for quick turns and easy navigation. Additionally, I consider the scrubber’s weight and balance to prevent tipping and guarantee it handles uneven or inclined surfaces without difficulty. These features collectively guarantee efficient, effortless operation in busy, obstacle-filled environments.

Durability and Build

A forklift-towed industrial scrubber must be built to last, especially in demanding environments. I look for models with a solid steel or polypropylene body, as these materials withstand harsh conditions and resist damage. Heavy-duty components like alloy steel handles and replaceable bristle strips enhance durability, ensuring the equipment can handle frequent use without quick wear. The frame and support structures should resist corrosion, impact, and general wear over time. Reinforced welds and secure fastening mechanisms are essential to maintain integrity during tough operations and handling. Choosing a scrubber with high-quality materials and solid construction standards reduces the risk of breakdowns and lowers long-term maintenance costs. Durability isn’t just about strength—it’s about reliability in the most challenging settings.

Maintenance Requirements

Durability and build quality set the foundation for a reliable forklift-towed industrial scrubber, but maintaining it properly guarantees it keeps performing at its best over time. Regular upkeep involves checking and replacing brushes, squeegees, and filters to ensure peak cleaning. Scheduled inspections of the motor and electrical parts help prevent unexpected breakdowns and extend the machine’s life. It’s also essential to clean and sanitize the solution and recovery tanks regularly to prevent bacterial growth and clogs. Lubricating moving parts like wheels, hinges, and drive mechanisms reduces wear and keeps operation smooth. Following manufacturer-recommended maintenance schedules and keeping detailed service records help identify issues early and protect your warranty. Proper maintenance isn’t just about longevity; it’s key to consistent, efficient cleaning performance.

Budget Considerations

Choosing the right forklift-towed industrial scrubber starts with establishing a clear budget that accounts for both initial costs and ongoing expenses. Industrial scrubbers vary widely in price, from basic models costing a few thousand dollars to more advanced units exceeding ten thousand. It’s essential to regard the total cost of ownership, including replacement parts, repairs, and operational costs like power and accessories. Setting a realistic budget helps you avoid overspending on features your environment doesn’t need. Comparing the cost-effectiveness of different models ensures you select a scrubber that offers the best balance of affordability, durability, and performance. By carefully evaluating your needs and expenses, you can make a smart investment that delivers efficient cleaning without breaking the bank.

Frequently Asked Questions

What Safety Features Are Included in Forklift-Towed Industrial Scrubbers?

Forklift-towed industrial scrubbers come equipped with essential safety features like emergency stop buttons, safety alarms, and automatic shut-off systems. I’ve also seen models with hazard warning lights, non-slip handles, and protective covers for moving parts. These features help prevent accidents, protect workers, and guarantee smooth operation. I always recommend choosing scrubbers with thorough safety measures, especially for busy industrial environments, to keep everyone safe and the workflow uninterrupted.

How Do Maintenance Costs Compare Across Different Scrubber Models?

Maintenance costs vary across different forklift-towed industrial scrubber models, and I’ve found that higher-end models often have higher initial costs but lower long-term maintenance due to better build quality and advanced features. Cheaper models may save money upfront but tend to need more frequent repairs and replacements. I suggest considering total cost of ownership, including parts, labor, and downtime, to find the best balance for your cleaning needs.

Are There Eco-Friendly Options for Forklift-Towed Industrial Scrubbers?

Yes, eco-friendly forklift-towed scrubbers are becoming more common, like a gust of fresh air in industrial cleaning. I’ve seen models that use rechargeable batteries and biodegradable cleaning solutions, reducing environmental impact. These scrubbers are like a conscience you carry along—powerful yet gentle on the planet. Switching to eco options not only helps the environment but also boosts your company’s reputation, making cleaning greener and smarter in 2025.

Can These Scrubbers Operate Effectively on Uneven Warehouse Floors?

Yes, these scrubbers can operate effectively on uneven warehouse floors. I’ve found that many models feature adjustable brushes and flexible wheels, allowing them to adapt to different surface levels. This guarantees thorough cleaning even on rough or uneven terrain. With the right model, you’ll get consistent results, reducing cleaning time and improving overall efficiency. I recommend checking specific features to match your warehouse’s floor conditions for ideal performance.

What Is the Typical Lifespan of a Forklift-Towed Industrial Scrubber?

A typical forklift-towed industrial scrubber lasts around 5 to 10 years, depending on usage and maintenance. I’ve found that regular servicing, proper storage, and using quality parts can extend its lifespan considerably. If you keep up with routine check-ups and avoid overworking the equipment, you’ll get the most out of your investment and ensure efficient cleaning for years to come.

Conclusion

If you’re serious about cleaning efficiency in 2025, you can’t ignore these top forklift-towed scrubbers. Each one offers unique advantages, but the real game-changer could be just around the corner. Are you ready to upgrade your cleaning arsenal and discover what’s next? Stay tuned—because the best choice might surprise you and redefine how you approach industrial cleaning forever. The future of spotless floors awaits, and it’s closer than you think.